RPAS-LM-PQ-1-2200X2600-B-ZS-VR2-LH50,RH360°,UTC,AFC-3P380V

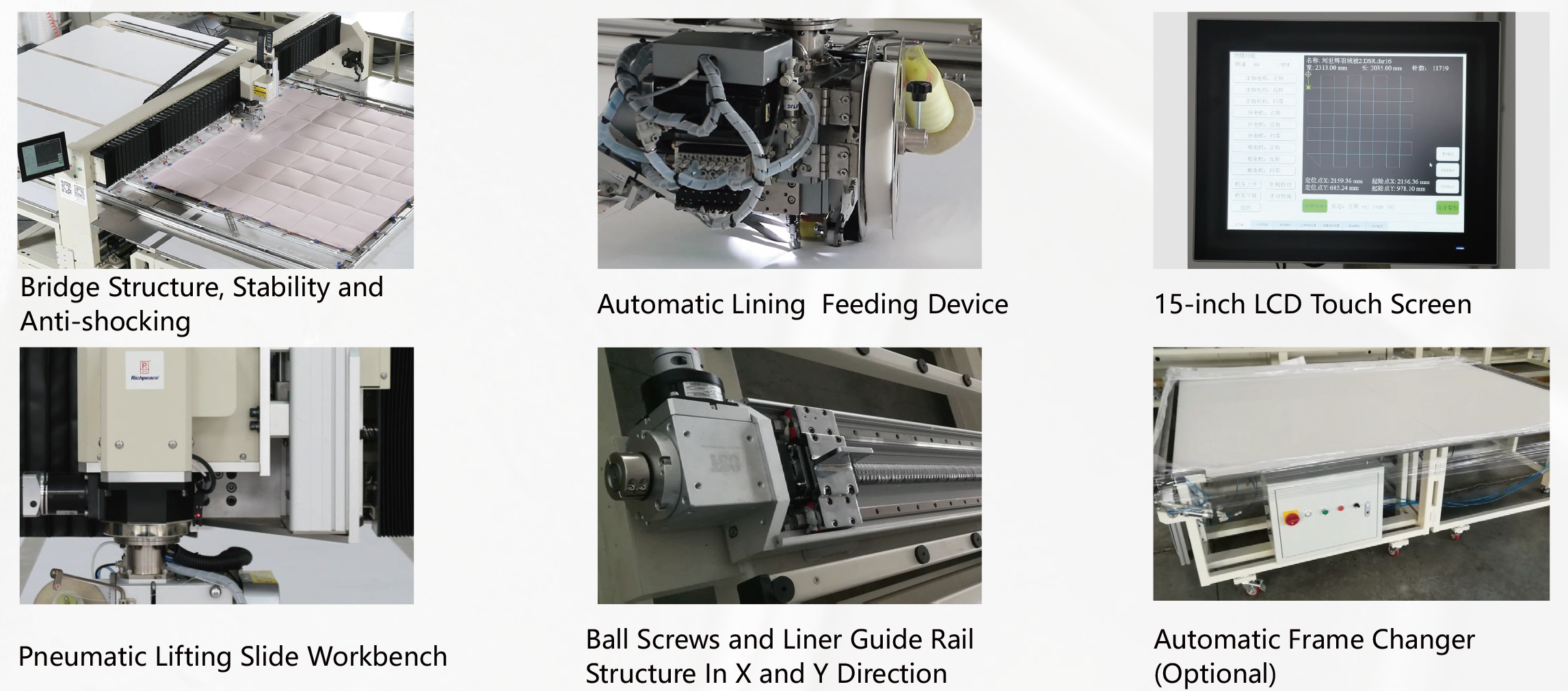

1. X and Y directions are driven by ball screws and linear guide rail, which ensures stable performance and stitch precision during high speed working, and enhances machine life span.

2. The baffle feeding device driven by servo motor, can feed the vertical lining automatically and cut it to the set length according to the sewing schedule.

3. Baffle conveyor speed is adjustable according to the sewing speed automatically.

4. 7-axis servo and ball screw to ensure high precision quilting.

5. Quilting head and rotary hook rotate at 360°, and adjust the direction according to the stitch track to ensure positive stitch at any time.

6. Diversifying products, Free design and quilting any pattern.

7. High speed lifting sewing head, meets the requirement of different thickness.

8. Richpeace independent sewing computer control system, ARM core and LINUX system.

9.DLC diamond coated needle rod and spindle, wear resistance, High-speed operation under the condition of no or little oil.

10. SMC Auto lubrication system, automatic oiling.

11. Automatic thread trimming.

12. Intelligent system extension (optional) : can be connected with the third-party CNC machinery

| Model | RPAS-LM-PQ-1-2200X2600-B-ZS-VR2-LH50,RH360°,UTC,AFC-3P380V |

| Speed | 3000RPM, Normal Speed1800-2500RPM(depends on the material and stitch length) |

| Power Supply | 3 Phase 380V/50Hz |

| Power | 6kW |