1. The large hopper device meets the load-bearing requirements of 0-300kgs fabric roll (diameter less than 1m).

2. On LCD touch screen, spreading length, number of layers, speed and spreading mode can be set freely.

3.Equipped with remote control, it can remotely control the operation including start, stop, feed and retract within 30m.

4. Supplied with automatic edge matching function and layer counting function.

5.With the convenient fabric loading structure, one worker can complete the feeding work, and it can also be equipped with automatic fabric loading device to further reduce the labor intensity.

6. During emergency stop, the spread fabric will not be dragged and deformed.

7. The multi-stage distribution structure ensures the smoothness of the spreading.

8.If the power is cut off during working, the original setting information is still saved after power on, and the spreading can continue.

9. All components are supplied by international famous brands to ensure the stability and lifespan of the machine.

Large hopper device

Meet the load-bearing requirements of 0-300kgs fabric rolls ( Φ ≦ 1m).

Walking encoder

Make sure that the head travels the same distance each time according to the setting.

Intelligent adjustable cutter device

The blade is easy to install and remove, and the built-in sharpening function improves cutting efficiency.

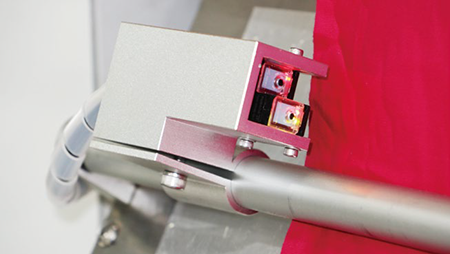

Safety protection inductor

The machine will stop automatically to ensure personal safety by sensing human signals within 0.5m around the machine.

Intelligent touch screen operation

International PLC control system, stable performance, easy maintenance.

Automatic edge alignment sensor

The fabric edge sensor adopts the infrared diffuse reflection technology of international famous brands, and its sensitivity is further improved.

| Model | RPSM-NM-1-1000X1800-C-N300-NA-1P220 |

| Speed | ≤100m/min |

| Power Supply | 220V,50Hz |

| Power | 3kw |