Release Time:2021-01-21

Heavy Secret - The key process of Richpeace automated quilt production line.

With the concept of healthy living enjoys popular support, the changing frequency of home textile products is getting higher and higher, and the quilt core will inevitably move towards quick sales. The new market calls for new production operations: higher capacity, less consumption, less labor. Quilt automation production line came into being. The next issues, we will analyze the key aspects of automation quilt production line one by one.

The key process of Richpeace automated quilt production line: Computerized multi-needle rotary hook quilting machine + Automatic four-sided overlock sewing machine.

The scope of application

Duvet, Quilt Cover, Bed hats, Mattresses protector, Mattresses, Blankets ect.

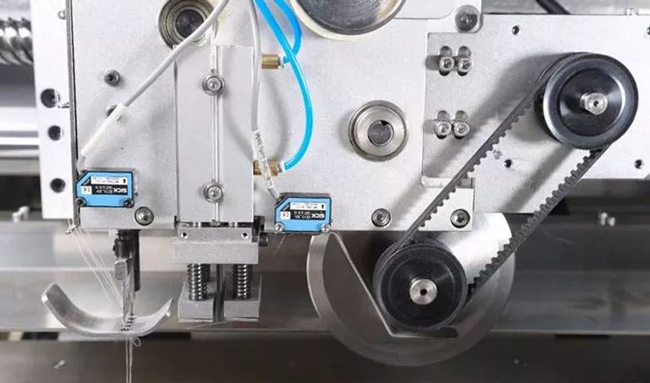

Current heavy-Richpeace automatic four-sided overlock sewing machine.

Richpeace automatic four-sided overlock sewing machine, applied to the cutting process of bottom cloth and silk wadding after quilting, cross cutting and edge cutting.

Richpeace automatic four-sided overlock sewing machine compared to the traditional process:

Solve the issue of broken stitch line at quilt cutting position;

Reduce the hemming difficulty, improve the hemming quality;

Significantly reduce the material consumption in the production process;

Performance Characteristics

Cross cutting and stitching.

Stiching both sides when cross cutting.

Edge cutting and stitching

Stiching both sides when cutting edges.

Knowledge Sharing

Quilting stitches after cutting will inevitably appear broken stitch line at quilt cutting position, the thicker the material, the more broken stitches, further affecting the follow-up hemming process. The more broken stitches, the more materials will be cut. It will cause the consumption of mass production materials over time.

If Thick materials don’t go through cutting and stitching, the edge will be fluffy,the quality will be affected when hemming.

In addition, if only cutting not stitching after quilting, sewing shrinkage force will cause the bottom cloth shrinkage, affecting hemming process.