1. Automatic fish mask with 5-layer fabric forming process. One to two structure, the full production line includes one set mask blanking machine, two sets headband welding machine, one set distributing & conveying station, one set material loader and one set electronic control system. Exquisite structure, easy to operate, stable performance.

2. Automatic built-in nose-clip device, automatic feeding, cutting to length, accurate position.

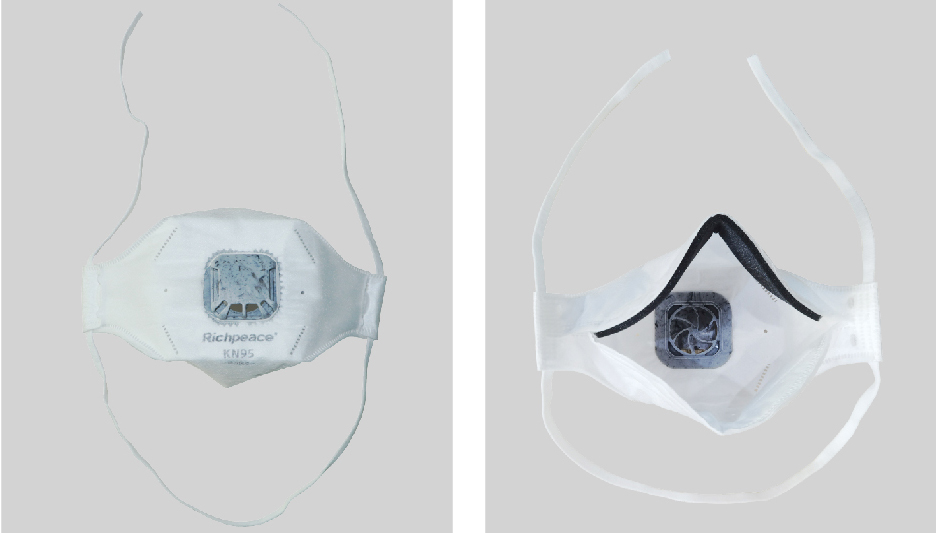

3. Optional device: automatic breath valve welding device, firm ultrasonic welding, accurate position.

4. Optional device: automatic sponge bar assembly device, automatic feeding with accurate position.

5. Headband welding device by ultrasonic can finish mask turning and welding in one time with stable and firm welding.

6. High speed: max. 17pcs/min.

| Model | RPSM-A-S+2LW-D-I-SC-UI2-SI-CH-3P380 |

| Size | 250mm×75mm |

| Speed | max. 17pcs/min. |

| Power Supply | Three-phase 380V/50Hz |

| Power | 23.8kW |

| Installation Area | 9400mm×5300mm×2200mm |