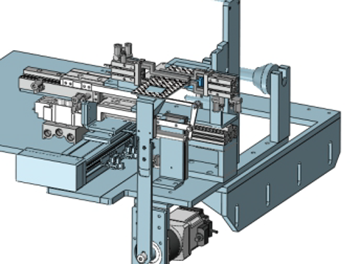

1. The whole machine consists of four parts: Automatic Feeding/Automatic Binding/Automatic Labeling/ Automatic Discharging.

① Automatic Feeding:The feeding tray automatically rises to a fixed position and the manipulator grabs the mat and moves itto the sewing area.

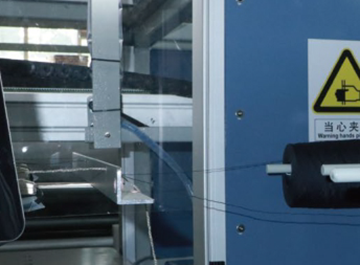

② Automatic Binding: The variable sensor detects the mat outline and transmits signals to the upper and lower press wheels to controlthe sewing direction.

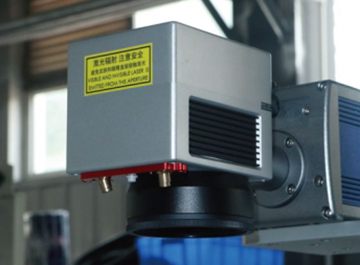

③ Automatic Labeling: Automatic stretching label length, cutting, marking.

④ Automatic Discharging: After sewing,the matis moved to the discharging tray by the blanking manipulator.

2. Automatic Trimmer, after sewing.

3. Optional automatic marking, for printing text, date, QR code and so on.

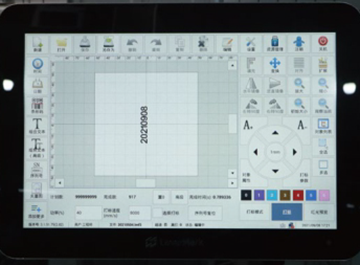

10.2-inch operating screen

Automatic feeding and discharging

Automatic labeling

Material inspection

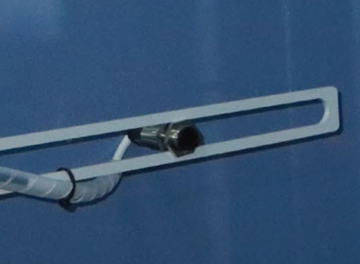

Thread break detector

Automatic trimmer

Automatic marking(Optional)

Marking operation panel(Optional)

| Model | RPAS-C10-ED-1-1300×700-UL-O-CN-MR,AF,AEG,ALF-3P380 |

| Size | Overlock Width 5mm, 10mm |

| Speed | 2000RPM |

| Power | 6kW |

| Installation Area | 4300mm×2400mm×2300mm(L×W×H) |