Recommend Models—Spreading Machine

RPSM-WF-1-1000×2500-C-W100-NA-1P220

RPSM-WF-1-1000×2800-C-W100-NA-1P220

RPSM-WF-1-1000×3000-C-W100-NA-1P220

RPSM-WF-1-1000×3200-C-W100-NA-1P220

Recommend Models—Cutting Machine(Other models can be customized)

RPAC-NM-MC6/9-1-2600×2600-SB-MH-P-3P380

RPAC-NM-MC6/9-1-2500×3200-SB-MH-P-3P380

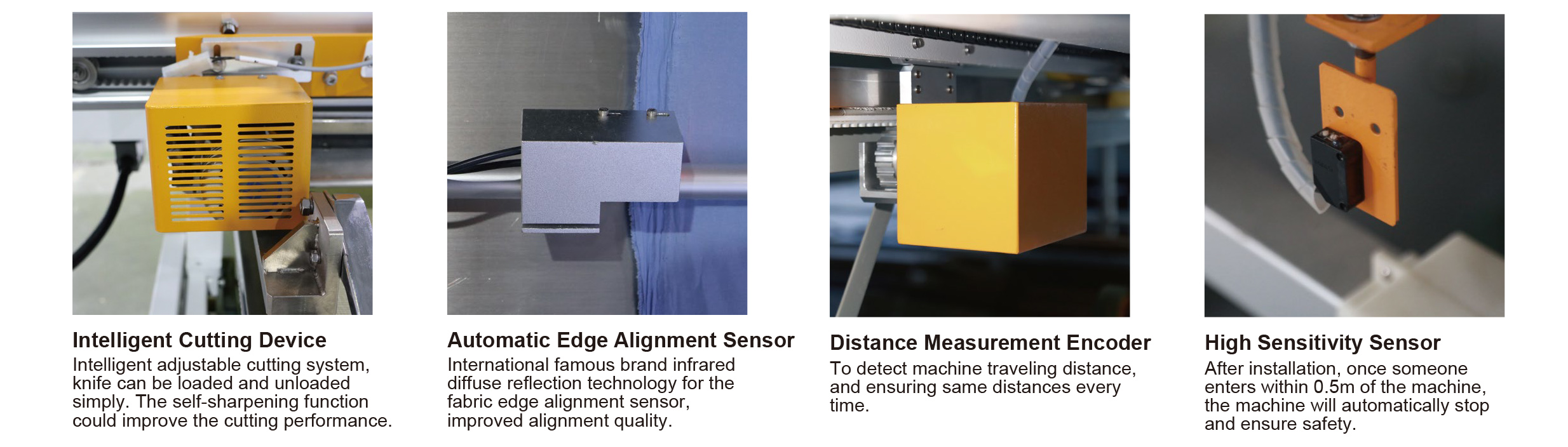

Features—Spreading Machine

1. International famous brand PLC control system: Touch Screen Intelligent Operation, stable performance, easy maintenance.

2. Digital LCD touch screen, free to set the fabric length, layers, moving speed, and spreading method.

3. Intelligently adjusting speed and distance, self-sharpening function, with neat and stable cutting.

4. Cutting bracket would be lifted automatically as per layers increasing.

5. Material shortage detection: automatically detect the spreading origin after starting up, and automatically return to the origin when no material.

6. When power interrupted, spreading set information can be stored after power reconnected, and find the origin to continue fabric spreading.

7. Automatic edge alignment and layers counting.

8. High sensitive senor to detect human being or obstacles barrier within 0.5 meter, to protect the operator and machine and ensure fabric edges aligned uniformly.

9. Equipped remote control can control machine start /stop and fabric feeding & collecting within 30 meters.

10. Breaking point detection: fabric inspecting machine can defect position which can be set by the length during spreading, machine will stop after auto-detection.

11. Front Fabric Clamp: Press & hold the laid fabric stack, prevent fabric moving during the spreading process.

12. Air Smoother (optional): For elastic, light and thin fabrics, it can help eliminate the air between the fabrics, making each layer of fabric more flat.

13. Zigzag fabric pressing device & rear pressing device (optional): suitable for zigzag spreading.

14. Auto-loader (optional): replace the manual loading heavy fabric roll to machine.

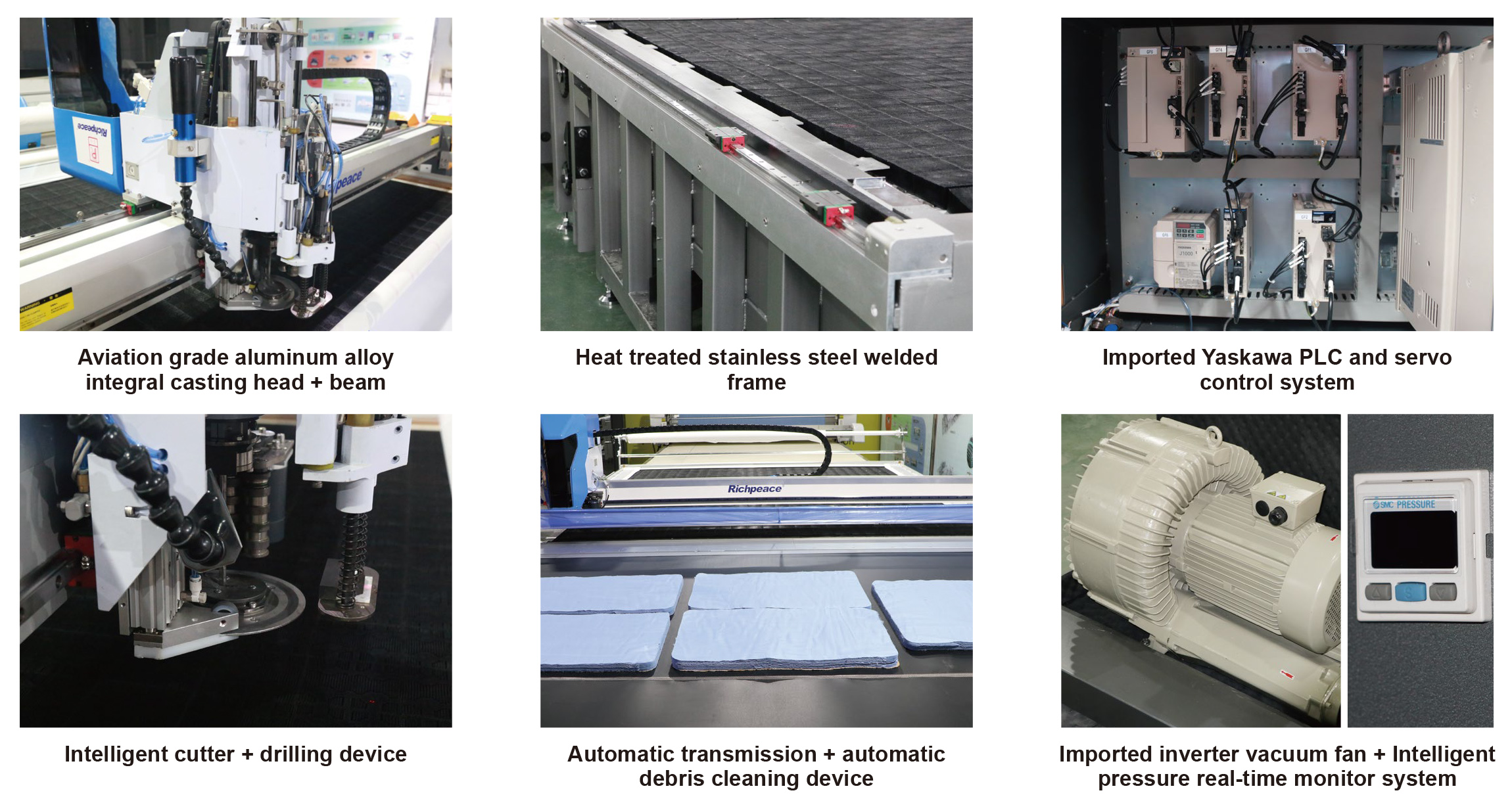

Features—Cutting Machine

1. There is a cutting ecosystem from Garment CAD software-CAM control system-Precision Machinery manufacturing, all with completely independent R&D intellectual property rights.

2. Cutting head is entirely aluminum casting structure, high-strength, long-life-span, light weighted and quiet. Key components are lubrication-free designed, avoiding fabric being-stained, easier daily maintenance.

3. Special coating treated to the high-frequency driving parts, enhanced durability, prolonging service cycle, and cost saving.

4. The intelligent cutter can intelligently change speed according to the cutting trajectory, automatically adjust the angle of the cutter, compensate the side stress, and ensure the consistency of cut pieces at the uttermost.

5. Double diamond automatic knife sharpening device, both sides of the blade are ground at the same time to keep consistency of blade two edges; computerized controlling the grinding times and automatically calculating the blade wear-loss, to ensure accurate cutting.

6. Real-time monitoring of cutting track, with fault alarm and remote diagnosis and troubleshooting.

7. Standard equipped with one set drilling devices, with Max. diamater of 4mm. Optional drilling device with 5mm-10mm diamater.

8. Heat Radiating System: equipped heat radiating devices in computer control cabinet and cutting head, prevent the machine core parts and components from over-heated damage during long-time and high-load running.

9. Automatic split of long-marker to multiply window for continuously cutting job, no need for second positioning nor bed-changing clearance reserving, can cut any length of patterns.

10. Conveyor belt with automatic discharging system, can intelligently identify cut pieces finished and delivers to material collection table.

11. Intelligently controlled vacuum pump, with real-time monitor system of the vacuum pressure and inverter loop-controlled, ensures sufficient and constant vacuum suction for the fabric.

12. Machine body can be made to split-structure suitable for shipping and overland transit, easy loading and transportation.

13. Equipped with one PC.

Configuration—Spreading Machine

Configuration—Cutting Machine

| Model | Recommend Models—Spreading Machine RPSM-WF-1-1000×2500-C-W100-NA-1P220 RPSM-WF-1-1000×2800-C-W100-NA-1P220 RPSM-WF-1-1000×3000-C-W100-NA-1P220 RPSM-WF-1-1000×3200-C-W100-NA-1P220 Recommend Models—Cutting Machine(Other models can be customized) RPAC-NM-MC6/9-1-2600×2600-SB-MH-P-3P380 RPAC-NM-MC6/9-1-2500×3200-SB-MH-P-3P380 |