Release Time:2021-01-19

September 26-29, 2019 Dieshiqiao Home Textiles International Expo, Shanggong Richpeace invited to participate!

China's Haimen Dieshiqiao, a former home textile market, is now becoming the “wind vane” of the world's high-end home textiles and the international textile production and trade center. From September 26th to 29th, the 2019 Dieshiqiao Home Textile International Expo will be held as scheduled. The event will bring together the world's home textile trends, build a high-quality, global trade bridge, and accelerate the acceleration of China's high-end home textiles to the world.

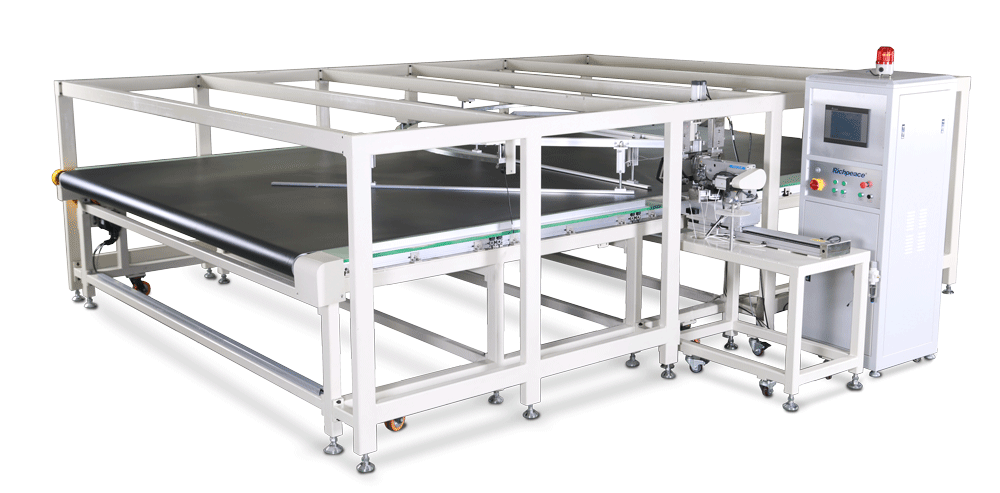

Richpeace core automated production line

Large rotary hook multi-needle computer quilting machine + automatic lock four-sided machine + automatic package four-sided machine

Scope of application

Products such as cores, bedspreads, mattresses, mattress protectors, mattresses, blankets, etc.

The key link -L1500 quilting machine

Performance characteristics

Richpeace high-speed multi-needle quilting machine releases the carding machine capacity to a large extent;

A total of 1500RPM, 2000RPM, 2800RPM three models;

Different speed models correspond to different production modes;

The production capacity can reach 9-15 meters / minute, which is 3-4 times of the ordinary multi-needle quilting machine;

The large imported 3x rotary hook is equipped with a bobbin-free bottom thread, which can greatly reduce the frequency of the bottom line replacement;

The unique needle-row adjustable mechanism makes the pattern design more diverse;

The needle row spacing can be continuously adjusted from 75-210MM, and the lower row head can be continuously traversed up to half head distance.

Key link - four seams

Richpeace automatic locking machine, used in the cutting process after the quilting of the bottom cloth and the silk cotton, that is, the cross cutting and the two sides cutting.

Richpeace automatic locking quadrilateral machine compared to traditional craft:

Solve the problem of incision blasting after multi-needle quilting; reduce the difficulty of thick material edging, improve the quality of edging; greatly reduce the material consumption in the production process; performance characteristics

Horizontal seam crimping: cross cutting and simultaneous crimping on both sides of the slit

Longitudinal seam crimping: Sewing the crimping line at the same time

Key link - automatic edging

Richpeace automatic four-side machine for automatic wrapping and labeling of cores, bed covers, mattress protection mats, etc., can be processed with the core production line to achieve automatic edge wrapping, or can be used separately. Fully automatic edging of finished products after sewing.

Performance characteristics

Richpeace independently develops electronic control systems;

The 3300mm wide belt conveyor and the 1800mm semi-circular guide rail can be used to sew quilts of common specifications;

The machine head automatically supplies oil to reduce noise and extend the life of the machine;

The elastic presser foot can be raised to ensure the beautiful stitching;

Automatic trimming function ensures that the materials are neat and edging before sewing;

Automatic finishing device, automatic finishing device to ensure the aesthetics of the edge joint.

Knowledge sharing

Ordinary multi-needle quilting machines have low speeds and linking with the card will limit the capacity of the card.

The quilting stitches will inevitably explode after being cut. The thicker the material, the more the number of blasting needles will affect the subsequent edging process. The multi-materials that are blasted will have to be cut more and will not be covered. Will affect the quality of the product. Over time, it will cause a large amount of production materials to be consumed.

If the thick material is not sewn, the edge will be relatively fluffy, and the operation is difficult and wrinkled, which affects the quality.

In addition, if only the line is not cut after quilting, the sewing contraction force will cause the bottom cloth to shrink, affecting the effect of the subsequent edging, resulting in uneven edges and the like.

Automatic edge wrapping machines in core automated production lines typically require a two-layer structure or a multi-site layout.