Release Time:2021-01-22

With the concept of healthy life becoming more and more popular, the replacement frequency of home textile products is getting higher and higher, and the quilts will inevitably move towards fast marketing. The new market calls for new production models: higher production capacity, less waste, less labor.Automation quilts production line came out.

Richpeace Quilts Production Line Large size rotary hook multi needles quilting machine +Automatic 4 sides sewing machine+Automatic 4 sides blinding/taping machine

Application: Quilts,bedding sheet,cover,mattress ,and blanket ects

Richpeace high-speed multi-needle quilting machine is the fastest multi-needle quilting machine in the world, which can release the production capacity of carding machine to the greatest extent;

There are 3 speed model :1500RPM,2000RPM,2800RPM;

Different speed model corresponds to different production mode;

The maximum production capacity can reach 9-15 meters per minute, which is 3-4 times that of the normal multi-needle quilting machine;

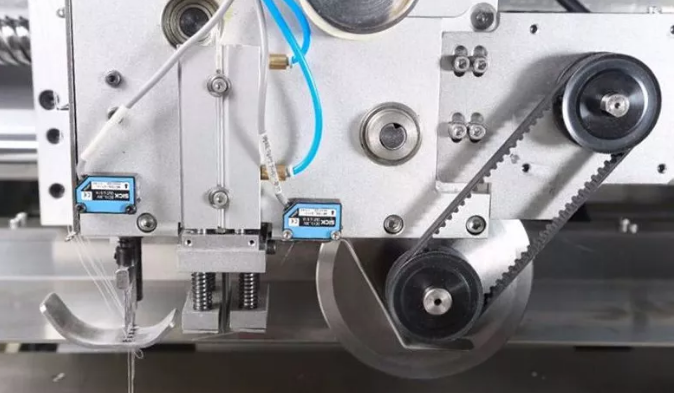

Super large 3 times rotary hook with no core bottom thread, can greatly reduce the bottom thread replacement frequency;

The unique needle row adjustable mechanism can make the pattern design more diverse;

The needle raw distance can be adjustment from 75-210MM,the lower row head can be continuously transverse, up to half head distance.

Above picture is Richpeace Customer Factory in Europe. The production line is combine by carding machine, high-speed multi-needle quilting machine, 4 sides sewing machine ,4 sides taping machine and hanging Three workers ,10 hours ,2300 pieces quilts.

Key Point -4 sides sewing machine compared with traditional way, Solving the problem of thread blasting after quilted,educe the difficulty of thick material tape blinding, improve the quality of tape blinding, reduce material waste in the production process.

Corss sewing and pressing :cross cutting while pressing both sides sewing lines.

Vertical sewing and pressing:2 sides edge cutting while pressing the sewing lines.

Key point-Automatic 4 sides Taping

Richpeace automatic 4 sides taping machine is used for automatic taping and trademark attaching of quilts, bed cover, mattress protector pad and other products. It can be processed with the whole quilts production line to realize automatic taping process, and can also be used separately in the automatic taping process of finished products after quilting.

Richpeace independent computer and control system;

Width 3300 mm ring conveyor belt, radius 1800 mm , can sew normal quilts sizes ;

Automatic head oil supply,reduce the noise, prolongs the machine life;

Lifting pressor foot to ensure the perfect sewing stithes;

Automatic edge cutting function to ensure that the material neatly before sewing and taping;

Automatic finishing device, automatic finishing device to ensure the beauty of the taping joint.

Normal multi-needle quilting machine speed is low, and will reduce carding machine capacity.

After cutting process ,the quilted lines will blow up,the thicker the material, the more the number of stitches blow up, which will affect the tapping process, the more materials will be cut or it can not be blinding well,then will affect the quality of the product. Over time, a large amount of production materials will be consumed.

If the thick material is not pressing through the edge, the edge will be more fluffy, the operation difficulty is high and easy to wrinkle, which affects the quality.

In addition, if only the thread is not pressed after quilting, the sewing shrinkage force will also cause the bottom fabric to shrink, which will affect the effect of taping edge and cause the uneven edge of taping and so on.

The automatic 4 sides taping machine in the quilts automaic production line generally needs to be equipped with double-layer structure or multi-site layout.