In the knitted sweaters of the production process, including design, sewing, plate making . Richpeace Sweater CAD System can provide you a complete solution. With the interface is simple, powerful, easy to learn and other features, can greatly improve production efficiency, shorten the production cycle, increase the technical content of products and added value, so that sweater products more competitive.

Main Feature

As a knitted sweaters production of professional software, including the style design, generate a process list, generate automatic computer flat machine file and other major functions, the following were introduced:

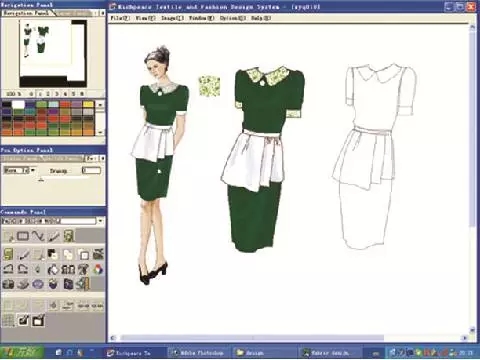

Style design module

1.Various drawing tools. Straight line, curve, rectangle, square, oval, round, multiple polylines, stitch, etc., can freely design a variety of knitted sweater style, flower pattern, jacquard pattern.

2.A wealth of auxiliary design tools. Copy, deformation, color integration, intelligent color, fill, etc., you can design a variety of clothing fabrics.

3.Various auxiliary operation switches. Transparent, raster, content, symmetrical drawing, small cursor, etc., can be set through the auxiliary switch more convenient and quick to do style design, flower design, jacquard pattern design.

4.Lots of special effects tools. Random pattern, special effects border, scattered point removal, image coverage, color gradient, scatter gradient, pattern experts, etc., to meet the special effects of fabric images, so that the effect of fabric style changes more richer.

5.Printed fabric design function. By splicing (horizontal, vertical), then back to the tool, you can design with printed characteristics of the fabric.

6.Print color separation design function. Through the channel color separation (RGB color separation, CMYK color separation), spot color separation (intelligent automatic separation, manual color separation), image screening template functions.

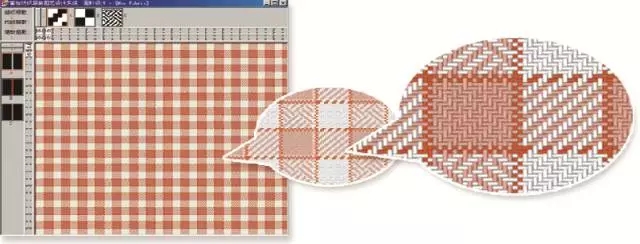

7.Woven fabric design function. Through the design of the organization and the yarn data, the organization and the yarn orderly combination of the formation of a variety of effects of woven fabrics, as well as the organization, yarn, fabric management operations. ion, you can create printed color film.

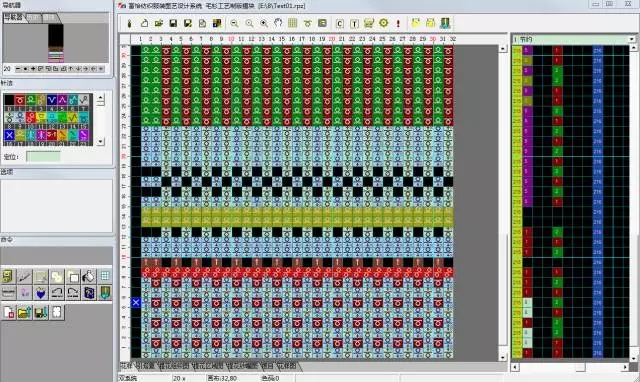

8.Knitted fabric design function. You can in the simulation of knitting display state, access to the design of a good knitted fabric, you can create a variety of knitted fabrics alone, you can also statistics knitted fabric statistics (color changing times, yarn length, yarn weight, yarn percentage ).

Process list module

1.You can enter the parts measurement size datas and related style characteristics, directly generate the process of each piece of clothing, to solve the problem of low efficiency manual calculation.

2.The pattern of the part of the clothing style can be personalized according to the habit and characteristics of the designer, and classification preservation needs to be satisfied.

3.Various clothing film process adjustment function. Add nodes, move nodes, delete nodes ,put the needle distribution, to meet the designer's details on the details of the patch.

4.Clothing piece color function. Including intelligent analysis between the color label, between the color folder, edit the color between the pieces, to meet the needs of intelligent color editing.

5. Vocabulary editing function. Lots of daily language vocabulary management editor, it’s convenient for the designer to quickly enter the daily language.

6.Parameter group setting function. Meet the different parameters of the set under the same style , calculate the requirements of the style process.

7.Automatic grading function. According to the different parts of the file of the size relative to the base size of the process of automatic calculation to meet the scramble division of the multi-size process list calculation needs.

8.Clothing note function. Provide straight lines, dotted lines, polylines, curves, arrow lines, text and other markings to meet the designer's description of the requirements of the process.

9.Database function. You can specify the style characteristics to save the process files, but also according to the specified style characteristics in the library file to find the characteristics of the process files, so that scare division can better do their own process of list classification management.

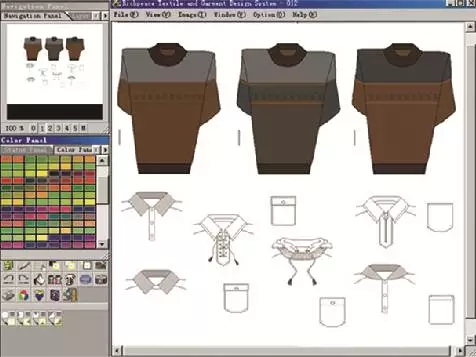

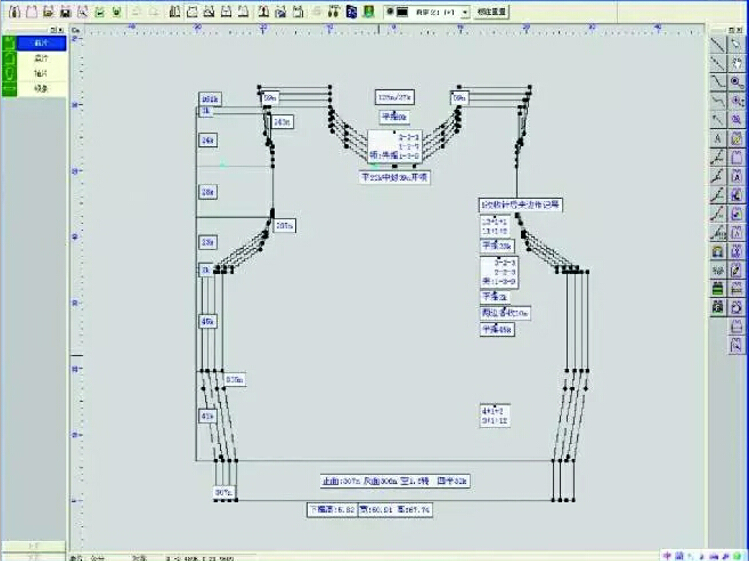

Plate making module

1.Various jacquard design tool. Including the drawing, the selection of windows, fill, copy, deformation, ranks, mobile, text, etc., use them to design a variety of common patterns, jacquard tricks, embossed tricks.

2.Lots of flat knitting machine tools. Including 1 × 1 transformation, go to the back bed weaving, modify the jacquard organization, yarn mouth separation, yarn mouth color filling, molding transformation, etc., they can be more convenient and quick to deal with the pattern before the set operation.

3.Pattern special effects processing function. Including the molding settings, sliding drawing, shadow effects, compression (separation), etc., use them to meet the special effects of the pattern processing.

4.Stitch, color size and the color scheme management function. You can edit the settings of the stitch color size display color, stitch symbol color, and management stitch-color scheme file.

5.Various patterns enter the machine file generation. Can be compiled to produce ordinary weaving patterns, ordinary jacquard pattern, local jacquard pattern, embossed pattern enter the machine file to meet the various patterns on the production of a variety of documents on the production needs.

6. Small map module function. You can quickly and easily design a variety of operation color size module, in the pattern of application module color size, and management module library.

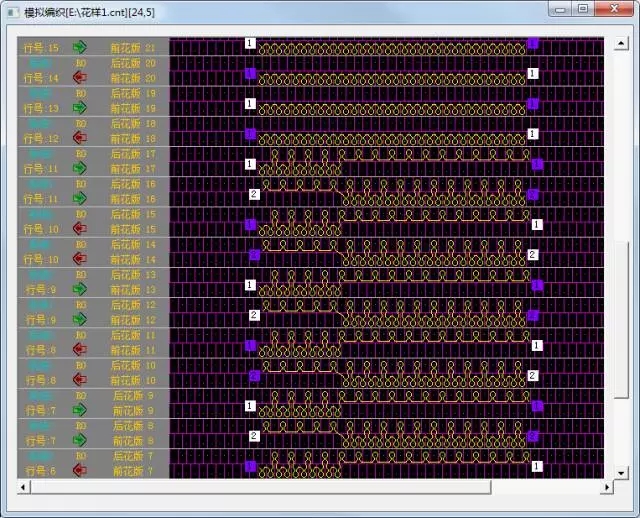

7.Weaving simulation display function. According to the CNT file and PAT file shows CNT action line to connect the front bed, after the bed of the needle weaving action symbols, the head weaving direction, and the use of knitting yarn nozzle number and other information.

Process formation

Input density, size and parameters and style characteristics, the system based on the input size, style features automatically calculate the number of revolutions per pin and the number of needles, eliminating the cumbersome manual calculation process.

Grading

Size grading: only the basic process of the size to adjust to the required requirements, click on the grading function, the other size will be based on input to the specifications of the data automatically generated.

Inter-color function

Clothing inter-color design easy to learn and easy to use, you can freely edit the color between the color and color effect map, you can change the color effect between the color label, you can on the front, after the film, the sleeve of the folder between the color, inter-color grading.

Print Process List

Typesetting printing knitted sweater process list content: project details, part size table, clothing film process, preview, row needle map, and so on.

Other Functions

In order to meet the needs of the majority of enterprises in the design of the style library, we strive for the rich and complete , can produce swallow collar class, pocket class, round feet and dresses, skirts, pants of the process.

Advantage

1.Save time and effort, efficient and fast to complete the style design;

2.The plate maker can easily change the pattern of the knitted sweater and make it into a fully automatic computer;

3.Will be able to better complete the design from the knitted sweater style to the process calculation, and then to the production process enter the machine file conversion, to achieve the true sense trinity fast work of the knitted sweater manufacturing.